Sitting on the back of a plain brown table at the back of a BMCC lab sits an 8” x 12” plastic board covered by a cluster of wires. At first glance, the odd looking object looks like a stripped down two wheeled model dune buggy. But all those wires are attached to a small copper and black colored box filled with programs called a microcontroller, or brain.

More wires extend from the microcontroller to two even tinier black objects that stick up from the plastic board’s sides. Those are the ultrasonic sensors, or eyes. A DC motor provides power to the sensors, and it’s the sensors that send messages that detail distance, space and direction back to the microcontroller.

The microcontroller then commands the wheels to turn while at the same time, providing the necessary intelligence for the object to perform tasks, and it’s that intelligence that makes this little object in the back of the BMCC lab a robot.

The learning model for the competition

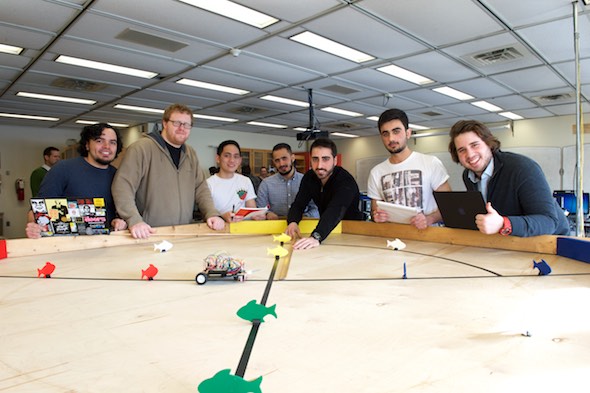

The little robot actually serves as a learning model for several BMCC students who’ve been gearing up since this past fall for the 2015 SUNY TYSEA robot building competition at Syracuse University this April.

Officially a robotics workshop, the students meet during Wednesday club hours to brainstorm and learn the hands on basics of building and programming a robot.

The workshop, sponsored by the Collegiate Science and Technology Entry Program, or CSTEP, includes mostly engineering and science students, many who’ve taken classes with BMCC science Professor Mahmoud Ardebili.

Ardebili says this group is especially robot enthused. They’d likely spend even more time developing and perfecting their model if given the chance. They even took time to meet up during the winter holiday break where they discussed ideas they’d had.

“They have to work together as a team. They brainstorm different ideas, then they’ll do a program, next they’ll try out those ideas on the prototype to see if those ideas work or not,” said Ardebili.

Rules of the game

The upcoming competition at Syracuse, called the TYSEA Fishing Derby, commands that each team design and build and autonomous robot that can collect colored fish cutouts and then deposit them into corresponding colored fish tanks. Meanwhile, the unpainted fish can be deposited into any fish tank.

The robots will have a maximum time of 120 seconds in each of their four allotted trials. Robots have to meet certain parameters, starting out with 8 by 12 by 10 inch high dimensions. The model can be expanded to any size during a trial session.

When the competitive trials conclude, the robots will be on exhibit.

The BMCC workshop group has divided themselves into three focus areas; programming, design and electrical circuits.

Each of the students has an interest in robotics and they all recognize the growth in job opportunities that incorporate engineering science and more specifically, the world of robotics.

The changing face of American Manufacturing

In fact, the nation’s job market has seen significant growth in robot related fields over the past decade and will likely continue to do so. According to the US Department of Labor-sponsored O*Net Online website, employment growth in robotics engineering is expected to be in the range of seven percent to 13 percent annually through 2018.

The students in the BMCC robotics workshop are getting a sample of the demands they’d face should they go on to pursue a robotics related career.

“It has to be functional, very accurate with its movements, but as far as what winning robot is, that’s some thing we won’t know until the competition,” said Engineering Science major Guillermo Herrera.

Once he graduates from BMCC, Herrera hopes to get into a four-year school and major in industrial engineering with a minor in robotics.

Mechanical Engineering student Gabriel Salvador agrees about the challenges of the competition.

Like Herrera, Salvador is hoping to pick up some practical research skills in the workshop that he can carry on to the next level of his education. Eventually, he hopes to explore a career in mechanical engineering.

Heading for a Robotics Major

Meanwhile, engineering science student John Woody hopes to head off to a four-year school and study computer engineering. Long term, his goal is to work and help design the machines that have revolutionized the way goods get manufactured in factories.

“There are a lot of cool things out there getting made by robotic arms, from huge machines to construction equipment on new high-rise buildings” he said.

Space, the final frontier

It could also be said that some of the students hear the voice of Hal, from the 1968 epic science fiction film, 2001 Space Odessy.

It’s no secret, that in the the decades since that film’s release, robotic projects, such as the Mars Rover and robotic arms on space stations have become reality. Some might say, robotics has revolutionized the exploration of the universe.

BMCC engineering science major Yuri Ghrimyan is aware of the exciting career possibilities. He said he joined the workshop to get some practical experience outside of a classroom. And he’s got his eyes set on the stars, someday hoping to incorporate his love of robotics within the aerospace engineering field.

“I just read an article about a huge grant to NASA from the Federal Government to support further aerospace engineering research,” said Ghrimyan.

He also admitted he’s having a great time working with the team as they prepare for a heated competition here on earth.

The skills to turn buildings green

Some of the students see themselves pursuing careers in building science, a vast field that’s been greatly influenced by growing efforts at more sustainable developments.

EnergyStar, the government-backed program that helps businesses and developers protect the environment through energy efficient construction, says that commercial buildings produce around 20 percent of the nation’s greenhouse gasses.

They say building owners can make sustainable investments by retrofiting, upgrading, or installing new heating and cooling equipment that helps meet reduced energy loads.

Engineering science major Mohamad Aljelub says he wants to be a mechanical engineer, focusing primarily on HVAC business, designing and implementing heating, ventilation and air conditioning in large commercial buildings. He pointed out that robotics is helping change the ways those new HVAC systems get implemented and operate.

“It’s a growing field in big cities,” he said, adding that so many large older buildings are changing their entire ventilation systems as they go green.

He too, sees his participation in the robotics competition as a chance to learn some skills that will benefit him as he pursues a career in the HVAC fieled.

The workspace verses the classroom

Engineering science major Yunus Kakar is transferring to State University of New York Stonybrook at the end of the spring. He’s enjoying the practical experience in the workshop.

“At school we deal with theories, versus the practical, “ said Kakar.

Like Ghrimyan, the aerospace industry has peaked his interest. Kakar said he is hoping to increase his skills in robotics as he continues his education.

Helping people through robotics

Robotic research has also been advancing what’s possible in the world of prosthetics. New modular and extensible limbs offfer levels of freedom and controllable dexterity that were unimaginable just a few years ago.

Student Omar Esteves, who hopes to go into the bio-medical field someday, has his eyes set on a career that helps those individuals who’ve lost limbs.

“With the robotics program, I’m getting practical experience in the hardware and programming, “ he said.

The ambition in the room on workshop day was palatable. And there’s little doubt, the enthused focus will serve the BMCC team members well come April.

“They may even have more than one robot at the competition, “ said Professor Ardebili.

In fact, he says, they may have two teams.

STORY HIGHLIGHTS

- 2015 SUNY TYSEA robot building competition at Syracuse University this April

- BMCC students recognize the role of robots in manufacturing

- The group is divided up into three focus areas; programming, design and electrical circuits